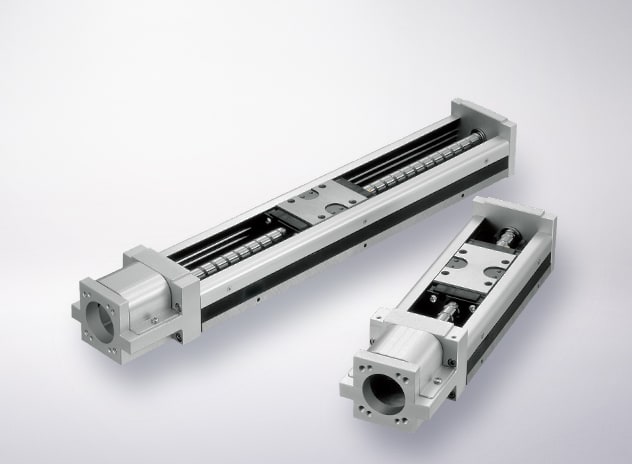

STROKE BALL SPLINE

SPLFS TYPE

The NB stroke ball spline SPLFS type is a high-precision, limited-stroke linear motion bearing capable of carrying radial load and torque at the same time. It operates with extremely low dynamic frictional resistance.

Features

The NB stroke ball spline consists of a cylindrical spline shaft with a transfer groove and an outer cylinder. The spline outer cylinder further incorporates an outer cylinder body, cage, side ring and steel balls. The cage has ball pockets to prevent the steel balls, which are the rolling elements from contacting each other, resulting in smooth linear motion.The cage is a steel ball non-circulation type cage and the cage also moves during linear motion, resulting in a limited stroke. It is recommended that 80% of the maximum catalog stroke be used as the travel.

Extremely low dynamic frictional resistance and low noise

The rolling elements are separated by ball pockets and do not contact each other. Although the stroke is limited, the rolling elements do not circulate, resulting in extremely low dynamic frictional resistance and low noise.

Compact

The outer cylinder outer diameter is approximately 20% smaller than that of conventional ball splines, contributing to space saving.

All stainless steel

All components are made of stainless steel for excellent corrosion resistance and heat resistance (operating temperature: -20 to 140°C), making it ideal for use in a vacuum or clean room.

lubrication

Two oil holes are provided in the oil groove on the outside diameter of the outer cylinder for easy oil supply design.

Structure

Structure of SPLFS type