特性

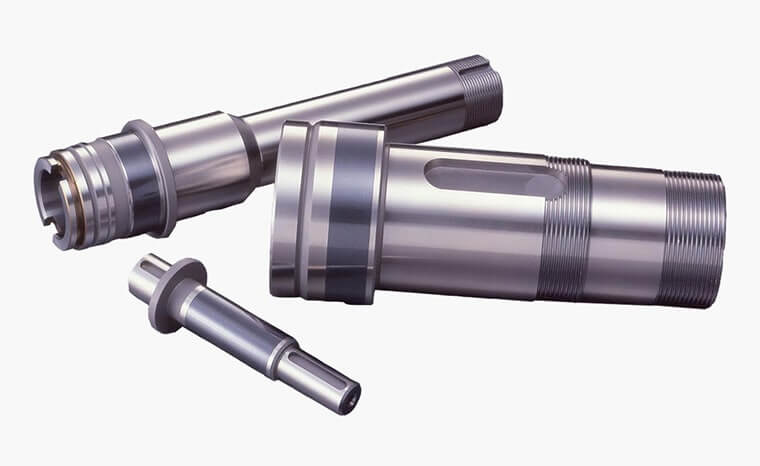

NB is active in a wide range of fields, from general industrial machinery to semiconductor manufacturing equipment, as well as various specialized machines, with its linear motion products.

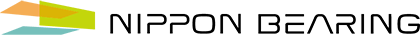

NB spindles backed by high technology cultivated over many years

We continue to supply high quality products by combining the technology and production processes we have developed over the years, the outstanding skills of our workers, and the introduction of the latest technology and machinery. We are confident that our high level of processing technology will satisfy our customers.

Consistency

In order to meet the various demands of our customers, NB provides products through integrated production from material arrangement to finished products, including turning, grinding, heat treatment, plating, coating, and other processes after receiving drawings.

Accuracy and Quality Control

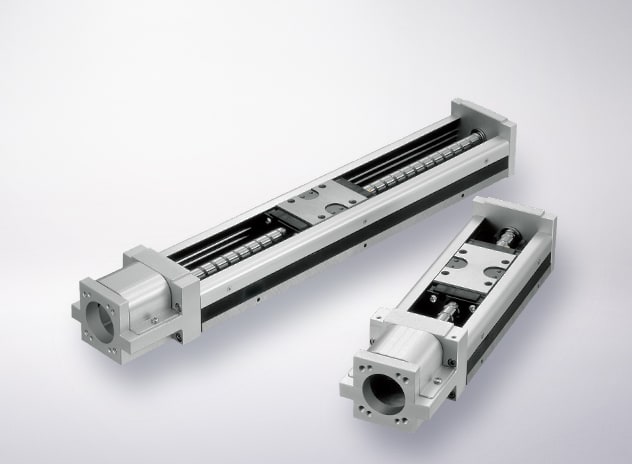

To ensure accuracy, NB controls the temperature in the inspection room to 20°C for product inspections.

High-precision processing technology, measurement technology, and final inspection

To achieve high precision, measurement technology is necessary along with machining technology to operate the machine tool by skilled machinists, and at NB, dimensions and precision are controlled through final inspection by skilled inspectors with reliable measurement technology.

constant-temperature laboratory

In a controlled constant-temperature inspection room, three-dimensional measuring instruments, shape measuring instruments, roundness measuring instruments, etc. are installed to guarantee quality under accurate inspections.

List of in-house facilities

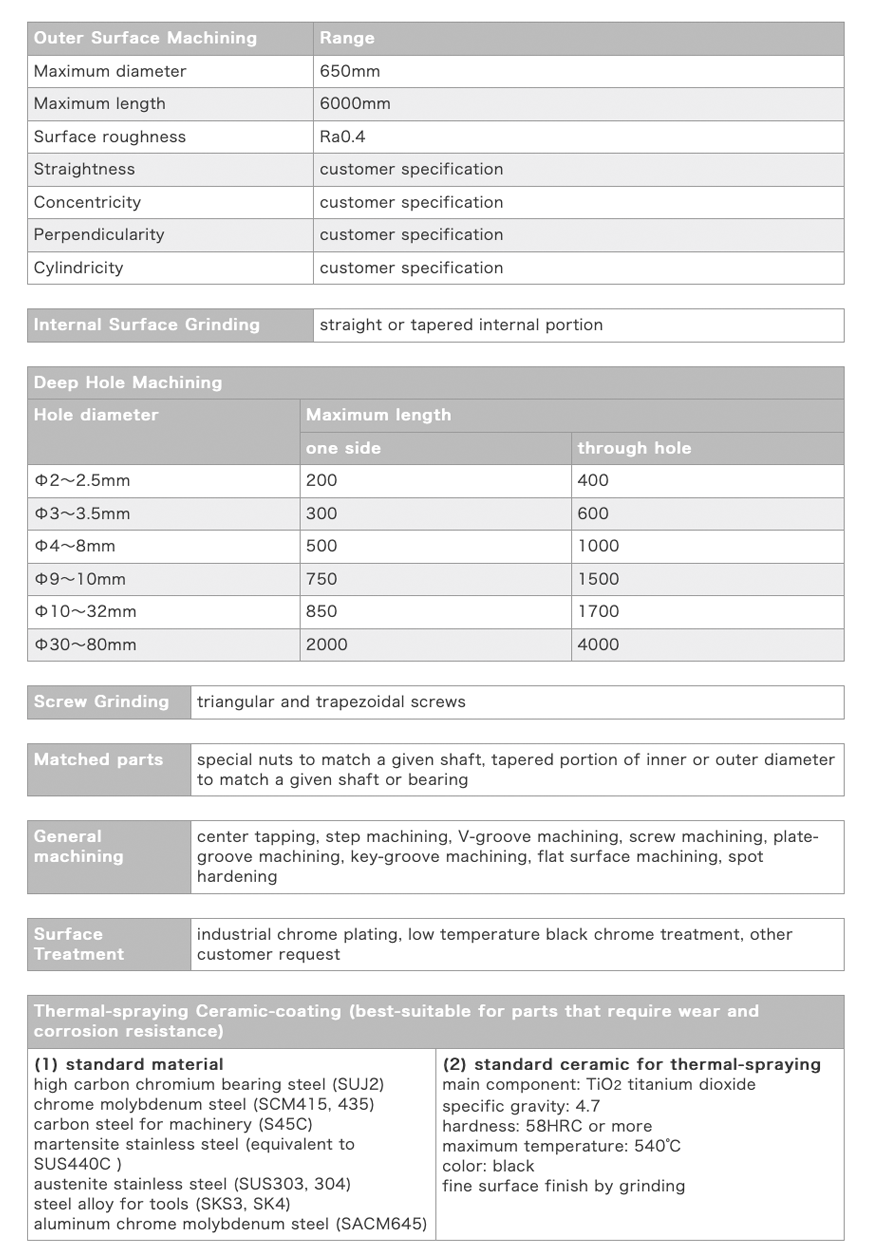

We would like to introduce some of the in-house facilities of Nippon Bearing to meet every need of our customers.

Q&A

Question and Answer

Is it possible to process in a short period of time?

We guarantee a short delivery time that is second to none. Please contact us with your machining drawings for details.

Can you handle mass production?

We accept orders regardless of order quantity. Please contact us.

What materials can be processed?

We specialize in machining high carbon chromium bearing steel (SUJ2), chrome molybdenum steel (SCM415,435), carbon steel for machine structural use (S45C), martensitic stainless steel (SUS440C equivalent), austenitic stainless steel (SUS303,304), carbon tool steel (SK4), alloy tool steel (SKS3), aluminum chrome molybdenum steel (SACM645). Other materials can also be processed. Please consult with us.

Can you grind stainless steel?

We can grind non-magnetic austenitic stainless steel (SUS303, 304, 316) and martensitic stainless steel (SUS440C equivalent). Other materials can also be processed. Please consult with us.

Is it possible to grind aluminum?

We are sorry. We do not accept this service.

Can I have an inspection sheet?

We ship with an inspection sheet. Please let us know at the time of quotation or order. Please also let us know what tests are required.

Is thread grinding available?

We offer thread grinding (triangular and trapezoidal screws). We can also handle all machined products including screw grinding.

What surface treatments are available?

Industrial chrome plating, electroless nickel plating, black dyeing, low-temperature black chrome treatment, etc. are available. Other surface treatments are also available. Please consult with us.